Stationary flare systems

Overview

Stationary flare systems are installed on site at a fixed position along with the necessary safety, ignition and control devices. Each stationary flare system is individually designed.

PREMA-SERVICE stationary flare systems have been reliably used worldwide for decades in compliance with the highest safety standards. Whether oil industry, refinery, chemical, steelworks or power supply – we design, build and supply stationary flare systems of all sizes, for all requirements and all specifications, as self-supporting construction, guy wired or as a derrick up to 175 m in height. Depending on the order, we take on responsibility for the entire project and hand over the flare system with all components and equipment as a turnkey project or only supply individual parts, such as flare heads and ignition. Our experts are also available for you after the commissioning.

Do you need a flare system for temporary use? PREMA-SERVICE provides transportable flares with all necessary accessories and personnel. Service, re-design, accessories and spare parts for flare systems can be found here

Elevated Flare with 3 Risers

COG Ground Flare

Standard flares

Flare systems with standard flare heads type RE are used when either no smoke-free combustion is required or the gas to be combusted is burned without smoke emission.

High-temperature-resistant steels, flame stabilizers and a special windshield ensure a stable flame over the entire operating range of the flare system and a long, maintenance-free service life. The special design of the flame stabilisers ensure good gas-to-air mixing and low speeds at the location of the pilot burners, ensuring safe ignition; even a purely electrical ignition via ignition rods is possible. A built-in, maintenance-free (possibly multi-stage) seal reduces the consumption of purge gas.

Smokeless flares

PREMA-SERVICE steam-assisted flares are used when heavy gases are to be burned without smoke and medium- or high-pressure steam is available. Various types of flare tips with steam injection into the flame inside and outside are available and are calculated for the respective application. Our special design offers low steam consumption, low thermal radiation, low noise and a long service life.

If steam is not available in sufficient quantities, a smoke-free combustion of heavy gases can also be achieved with air-assisted flare tips. Air-assisted flares use fans to generate additional combustion air and flow directly into the gas stream in the flare tip, therefore achieving smokeless combustion with a long service life.

Special air-assisted flare tips are available for applications like the conversion of existing flares to a smoke-free design. These flare tips allow a conversion with minimal downtime and low investment.

Low heating values

Ground flares

For applications where the use of a elevated flare is not possible, smoke-free combustion with a high burnout or a non-visible flame is required, PREMA-SERVICE offers ground flare systems.

In these systems, a multi-stage burner is completely enclosed by a thermal and sound-insulated combustion chamber. This solution offers many advantages:

- Clean, smoke-free combustion without steam or additional air

- No thermal radiation outside the system

- Low noise emission

- No visible emissions

- Large turn-down range

- Critical components are easily accessible

Ignitions

Pilot burners

PREMA-SERVICE pilot burners are available for all gas mixtures and can be equipped for electric ignition, flame front ignition or both types of ignition.

Properties:

- Long life due to temperature-resistant materials

- Low-temperature, weather and storm resistant (at least up to 70 m/s)

- Can be adapted to all gas mixtures by means of different nozzles and designs

- Easy assembly

- All flare tips can be upgraded

- Critical components are easily accessible

Flame front ignition

Electrical ignition

Monitoring and control

Pilot flame monitoring

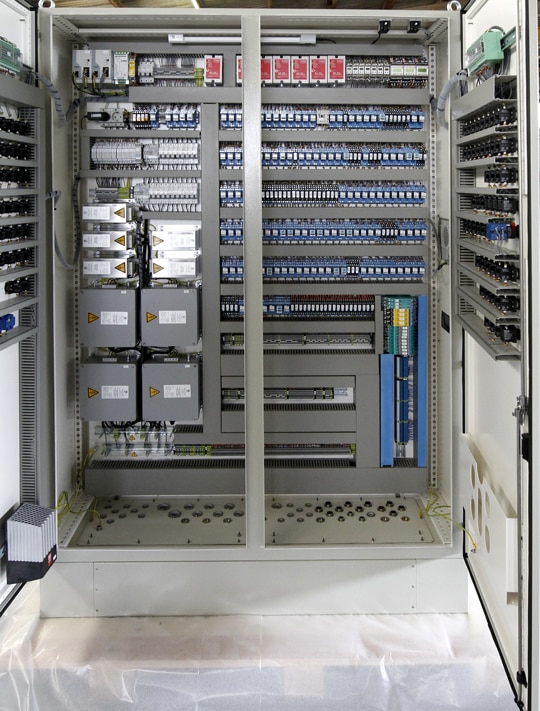

Controls

Steel construction

Several steel structures are available for high flares:

In a guy wired flare the flare riser is held in position by steel wires. This construction is economical but requires additional foundations and anchors for the wires and calls for a large space.

With the self-supporting design, the flare riser is so sturdy that it is not necessary to use bracing or other supports. A connected construction with several flares or flare tubes is also possible.

In the case of large flares, a derrick supports one or more flare risers assembled in the centre of the derrick or on one side. Special constructions allow the lowering and maintenance of the riser and the flare tip. Even without the use of a crane or while adjacent flares are in operation.

Accessories

Depending on the application and design, further process-specific components and systems are necessary for flare systems such as, for example,

- Gas pressure reducing station for pilot burners

- Equipment for reducing the consumption of purge gas (molecular seal, velocity seal)

- Separators for particles and liquids (knock-out drum)

- Water seal

- Aircraft warning lights (ACWL)

- Heating systems (electrical or with steam)

- Fans and compressors

- Pumps

All components can be ordered as part of a complete system or as a spare part.